Nitrogen Plants

Product Details:

Product Description

| ||||||

| First : BF Technology | ||||||

| ||||||

Third : The Plant

| ||||||

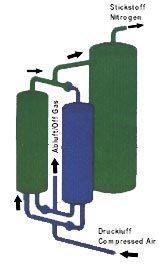

The first example concerns the particularly long plant life, the second the fully automated operation of the plant. In fact, after the first day there are no personnel costs since the plant runs fully automated and trouble-free. The low energy costs are doubly advantageous as they result in lower over-heads and a cleaner environment. Nitrogen is all around us, and it is surprisingly easily separated, given three things - our process, the CMS, and the plant. Facts and figures prove our performance - more than 5000 plants are in operation worldwide utilizing the BF-Process and the trend is rising. | ||||||

| In addition to nitrogen, hydrogen can also be separated from process and coking gas; methane from landfill and pit gas; and helium from natural gas. In these cases it is also true that the "simpler" the principle, the more broadly based is its success. | ||||||

| ||||||

Other Products in 'Nitrogen Plants' category

GST : 06AAACP0953G1ZP

|

|

|

|

|

INDCON BOILERS LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |